In the automotive industry, the untreated windshield surface may lack sufficient activation energy, making it difficult for materials such as coatings and adhesives to form strong chemical bonds with them.

The adhesion and durability of the windshield surface directly affect the performance and service life of the coating, adhesive and other materials. If the surface adhesion is insufficient, the coating and adhesive are easy to fall off or crack.

The plasma cleaner machine has the function of surface activation, through the action of plasma, it can completely remove the organic matter and other pollutants from the surface of the windshield, thus increasing the surface energy and improving the adhesion of ink, coating or other materials to the surface of the windshield.

Before the printing and bonding process of automobile glass, plasma cleaning machine and USC ultrasonic dedusting can be used to achieve the purpose of surface activation and fine dedusting.

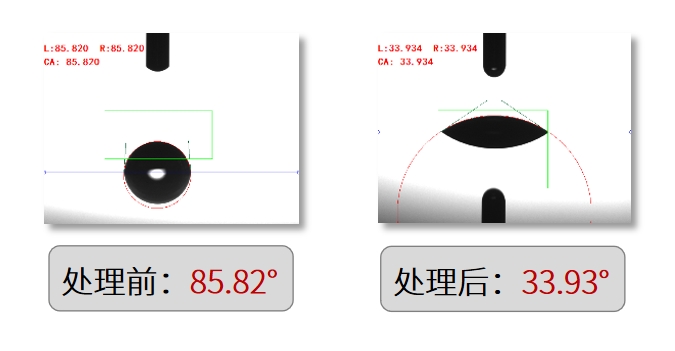

Plasma surface activation effect.

The surface was activated by atmospheric plasma cleaner SPA-2800, and the contact angle was measured by contact angle measuring instrument. After plasma treatment, the contact angle was reduced to 33.93 °.

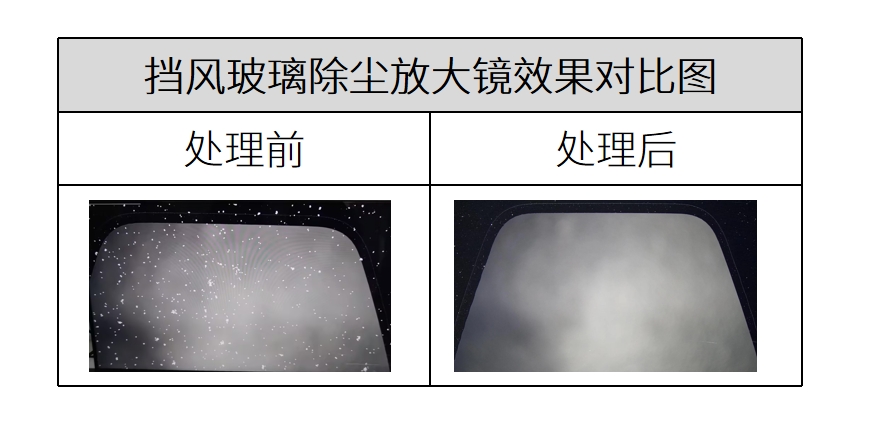

Dust removal effect of USC surface.

Sprinkle 100 grains of fine powder on the scratched glass surface and remove dust by USC. The effect is obvious after treatment, and the dust removal rate is 99.99%.