Why establish an electrostatic protection system?

With the increasing development of semiconductor manufacturing technology, the width and spacing of interconnect wires are getting smaller, and the integration density of integrated circuits is getting higher. At the same time, the problem is that the anti-static breakdown voltage of devices is also getting lower. Therefore, in the development and production process of semiconductor devices, it is necessary to pay attention to the issue of static electricity and take electrostatic protection measures.

The hazards of static electricity

Electrostatic adsorption

In the process of device production, due to the extensive use of instruments and materials made of quartz and polymer materials, their insulation is very high. Some inevitable friction during use will cause the accumulation of surface charges and increasing potential. Due to the mechanical effects of static electricity, floating dust in the workplace is adsorbed on the surface of the chip, thereby changing the impedance between lines and affecting the functionality and lifespan of semiconductor devices.

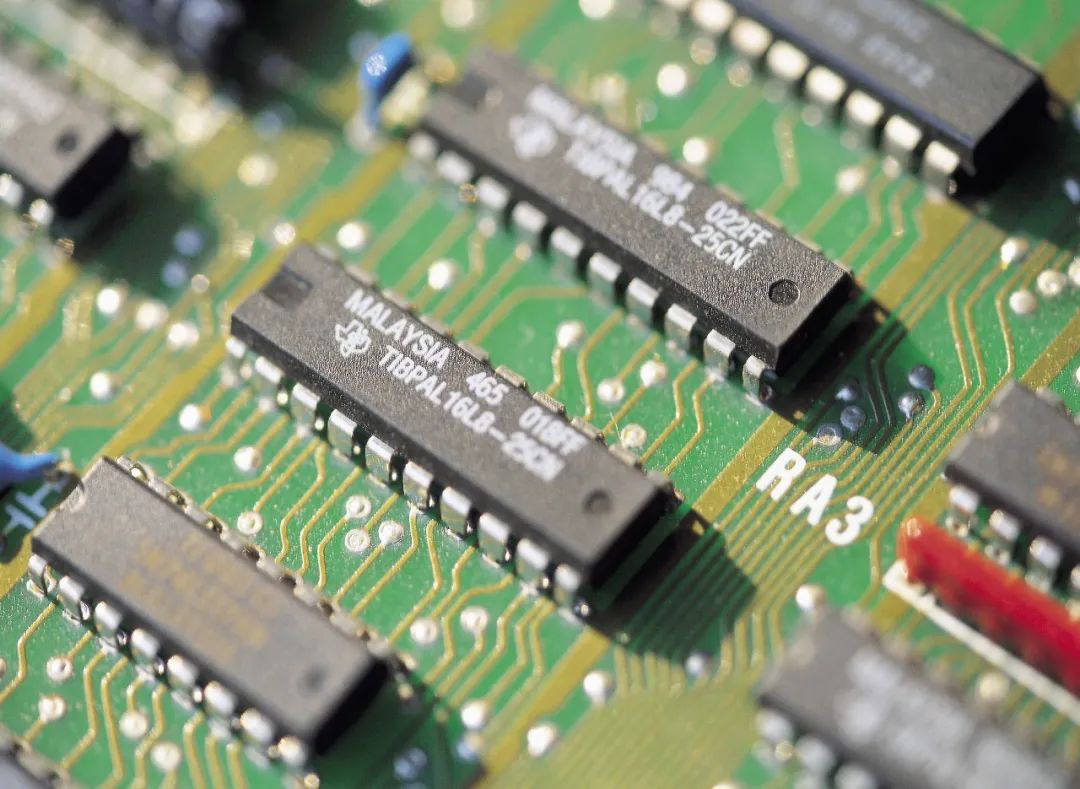

*Image: Internal circuit damage of the chip

Electrostatic discharge (ESD)

The electrical breakdown of components caused by electrostatic discharge is the main way of electrostatic hazards. The main mechanisms that cause device damage include thermal secondary breakdown, metal coating melting, dielectric breakdown, gas arc discharge, surface breakdown, and bulk breakdown. Electrostatic discharge may cause hard or soft breakdown of the device.

*Figure: Ablation caused by integrated circuit plastic packaging material in electrostatic discharge

What are the types of electrostatic protection measures?

① Internal protection methods for devices

In most cases, electrostatic discharge breakdown of components mainly occurs near the input end of the device, so the commonly used protection method is to create a protective circuit in the part related to the input end. In unipolar integrated circuits (MOS circuits), due to the high input impedance, high voltage is prone to occur at the input end. Therefore, protecting the circuit is essential, and commonly used methods include using diodes, transistors, Zener diodes, and spark gap protection.

② External protection methods for devices

The simplest way to provide external protection is to connect a resistor in series or parallel with a diode at the input end of the device. The function of the resistor is to limit the excessive electrostatic discharge current, increase the discharge time constant, and reduce the amplitude of the current pulse, while the diode can bypass the electrostatic energy. After adopting the above protective measures, the breakdown voltage resistance of the IC can generally be increased by 2-6 times, which to some extent protects the device from damage.

③ Protection of devices by anti-static systems

The specific measure to establish an anti-static system is generally to set up an anti-static work area. All personnel in this workspace must wear anti-static work clothes, shoes, and hats. The operator must operate on a workbench equipped with various anti-static devices. At present, the common anti-static devices on the market include ion nozzles, ion fans, and ion air rods. The choice of these three devices depends on the location of the equipment installation and the size of the anti-static range. Only by having a good understanding of electrostatic hazards in devices and actively preventing them can semiconductor devices be effectively protected from electrostatic hazards.