With the development of hybrid integrated circuits towards high performance, high density, high reliability, miniaturization, and low cost, higher requirements have been put forward for the packaging and welding process of chips. When connecting chips with substrates or shells, there are mainly two methods: conductive adhesive bonding and eutectic welding. Today, we will mainly study the eutectic welding process.

What is eutectic? The advantages of eutectic

Eutectic welding is an important method in microelectronic assembly, also known as low melting point alloy welding. Place a thin eutectic alloy sheet (eutectic solder) between the chip and carrier, heat it to the eutectic point of the alloy in a certain protective atmosphere to melt it, and fill it between the tube core and carrier. At the same time, a small amount of gold on the back of the tube core and the surface of the carrier will enter the molten solder. After cooling, it will form an atomic bonding between the alloy solder and the gold layer, thereby completing the welding of the chip and the tube shell or other circuit carriers.

Eutectic welding has the advantages of low connection resistance, high heat transfer efficiency, uniform heat dissipation, high welding strength, and good process consistency, and has gradually become one of the mainstream methods of semiconductor packaging welding.

Factors affecting eutectic quality and solutions

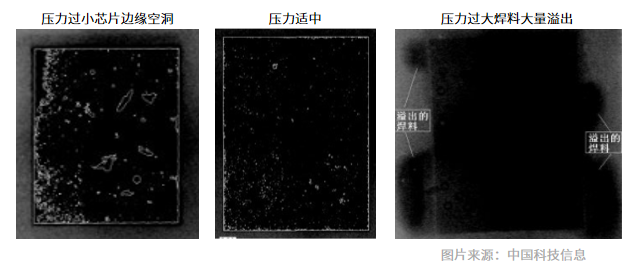

During the eutectic process, the wettability of the solder and the magnitude of applied pressure affect the welding quality, leading to problems such as high porosity and chip cracking, resulting in eutectic failure.

The void fraction after eutectic is an important detection indicator, and reducing the void fraction is a key technology for eutectic.

The main methods to eliminate voids are:

(1) Before eutectic, microwave PLASMA can be used to clean the substrate and solder surface, increasing the wettability of the solder;

The cleaning plan for substrates and solder is recommended to use Shengding's microwave PLASMA cleaning machine. It can directly import microwave PLASMA cleaning into the existing process, which is simple, convenient, and quickly improves the yield rate.

(2) Place a pressure device on the device during eutectic and directly apply positive pressure;

The setting of eutectic pressure parameters requires multiple experiments to obtain appropriate values. Excessive or insufficient pressure is not conducive to process control and welding reliability.

Shengding Microwave PLASMA Cleaning Plan

Advantages of Shengding Microwave PLASMA Products

● Plasma is not charged and does not damage precision devices

● Maintain low temperature during processing

● Fast reaction speed and short reaction time

● No electrode, no pollution source, long service life

● Can maintain plasma under high pressure

● Has a high degree of ionization and decomposition

● Microwave junction and magnetic circuit are compatible

● Low self bias requirement

● Stable and easy to control microwave generator

● High voltage source and generator are isolated from each other for safety