As a representative material of the new generation of semiconductors, gallium nitride (GaN) has the characteristics of large bandgap width, high critical field strength, high thermal conductivity, and high carrier saturation rate. It is an important semiconductor material in the manufacturing of high-power and high-frequency electronic devices. Among them, the Ohmic contact between GaN material and metal electrode has a significant impact on device performance. The device utilizes the Ohmic contact formed by the contact between metal electrode and GaN to input or output current. When the Ohmic contact resistance is too high, it will generate more Joule heat, shorten the lifespan of the device, and good Ohmic contact can reduce the on state resistance of the device, increase the current output, and have better stability.

Annealing temperature affects the quality of Ohmic contact

The preparation of gallium nitride ohmic contacts usually requires annealing treatment. The purpose of annealing is to change the structure and properties of the material through heat treatment, so as to form a low resistance contact between the metal electrode and gallium nitride. The quality of Ohmic contact formed between metal and GaN is affected by annealing conditions. The edges of a good Ohmic contact pattern should be kept flat, and there should be no metal bonding between electrodes that can cause short circuits. After annealing, there should be no metal side current.

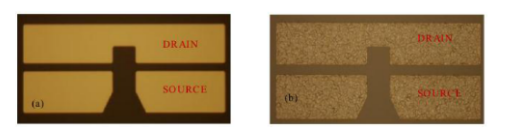

(a) Ohmic contact morphology before annealing (b) Ohmic contact morphology after annealing

(Image source network)

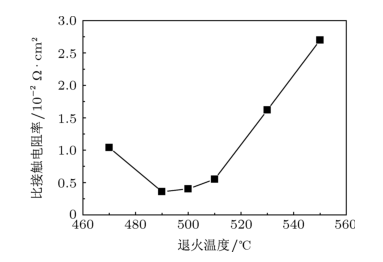

The annealing temperature, as an important parameter affecting the Ohmic contact performance, can lead to an increase in resistivity and a decrease in current if the temperature is too high or too low. Generally speaking, the higher the annealing temperature, the lower the specific contact resistance between the metal electrode and gallium nitride.

The functional relationship between specific contact resistivity and annealing temperature (Image source: CNKI)

However, when the annealing temperature is too high, it may cause damage to the gallium nitride material or melting of the metal electrode, which is not conducive to forming good ohmic contacts; When the temperature is too low, it can lead to the formation of high potential barriers between metals and semiconductors, hindering the transmission of charge carriers. Therefore, when annealing GaN ohmic contacts, the selection of annealing temperature conditions is particularly important.

The principle of Rapid Thermal Processing (RTP)

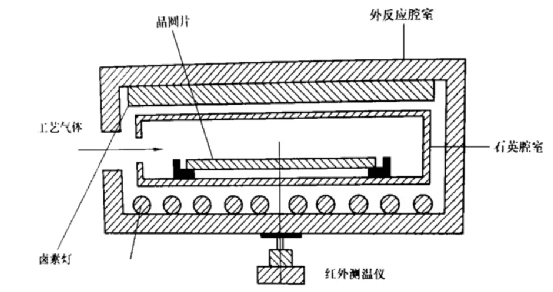

Rapid Thermal Processing (RTP) is a device used for semiconductor device manufacturing and material research. Its working principle is to process materials through rapid heating and cooling to change their properties or structure.

RTP Structure Diagram (Source Network)

Advantages of Shengding Rapid Thermal Processing (RTP)

The RTP Rapid Thermal Processing has the advantages of precise temperature control and fast heating speed, which can meet the requirements of Ohmic contact for temperature sensitive materials and structures. The process range of Shengding Rapid Annealing Furnace covers 200-1250 ℃, with a powerful temperature field management system. In addition, it can flexibly and quickly convert and adjust process gases, allowing it to complete multiple treatment processes in the same heat treatment process.

RTP temperature control of Shengding rapid annealing furnace -1000 ℃ process

Semi-automatic Rapid Thermal Processing

RTP-SA-12 is a semi-automatic vertical Rapid Thermal Processing with short process time and high temperature control accuracy. Compared to traditional diffusion furnace annealing systems and other RTP systems, its unique chamber design, advanced temperature control technology, and unique RL900 software control system ensure excellent thermal uniformity.

Product advantages

◎ Infrared halogen lamp tube heating, cooling using air cooling

◎ Both atmospheric and vacuum treatment methods can be selected, with gas purification treatment before intake

◎ PID temperature control for lamp power, which can accurately control temperature rise, ensuring good reproducibility and temperature uniformity

Fully automatic dual chamber annealing furnace

Compared to traditional diffusion furnace annealing systems and other RTP systems, RTP-DTS-8's unique cavity design, advanced temperature control technology, and unique RL900 software control system ensure excellent thermal uniformity.

Product advantages

◎ Infrared halogen lamp tube heating, cooling using air cooling

◎ PID temperature control for lamp power, which can accurately control temperature rise, ensuring good reproducibility and temperature uniformity

◎ Both atmospheric and vacuum treatment methods can be selected, with gas purification treatment before intake

◎ Two sets of process gases are standard and can be expanded to up to six sets of process gases

Desktop fast annealing furnace

RTP-Table-6 is a desktop 6-inch wafer rapid annealing furnace that uses two layers of infrared halogen lamps as a heat source for heating. The internal quartz cavity is insulated and insulated, and the outer shell of the cavity is made of water-cooled aluminum alloy, ensuring uniform heating of the product and low surface temperature. RTP-Table-6 adopts PID control, and the system can quickly adjust the output power of infrared halogen lamps, making temperature control more accurate.

Product advantages

◎ Double layer infrared halogen lamp tube heating, rapid nitrogen cooling

◎ Independently developed grouping arrangement of lamp tubes to improve temperature uniformity

◎ Using PID algorithm control, real-time adjustment of lamp power output

◎ The main interface of the software can display real-time parameters such as gas, temperature, vacuum degree, etc

◎ Automatically recognize error messages, and in case of abnormalities, the device will automatically protect itself