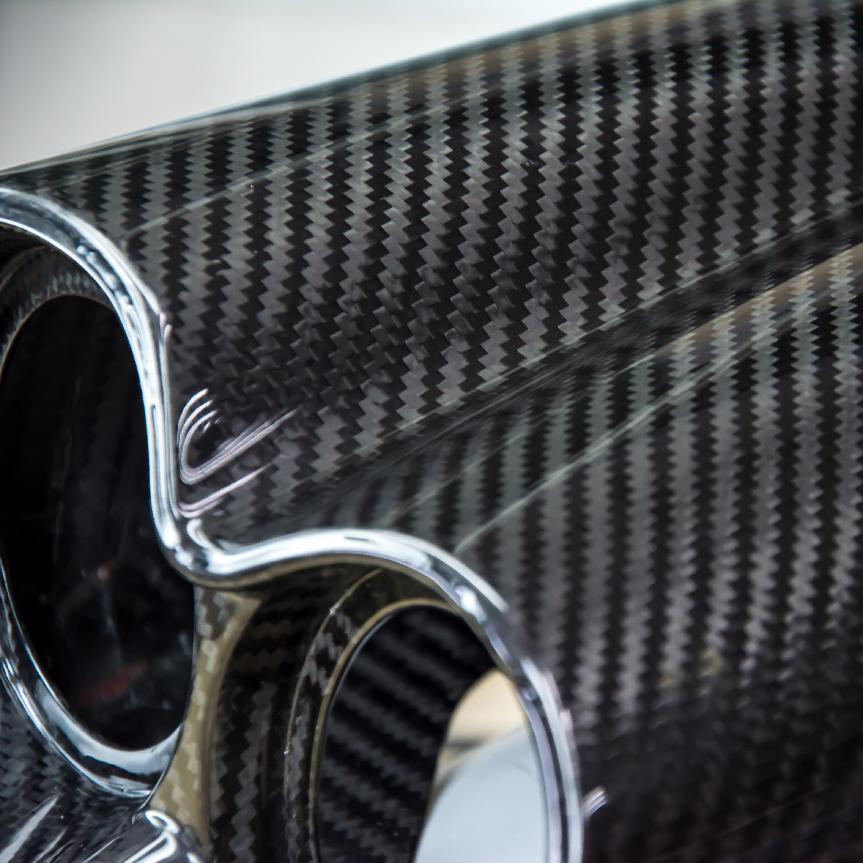

Carbon fiber materials are widely used in aerospace, automobiles, sports equipment and other fields. Carbon fiber itself has low surface energy and is chemically inert, which leads to the following bonding problems: pollutants such as release agents and grease hinder glue infiltration during production; smooth surface: the surface of the composite material is too smooth and the mechanical bite force is insufficient; lack of active groups: it is difficult to chemically bond with the adhesive. Therefore, it brings great difficulties to the bonding of carbon fiber.

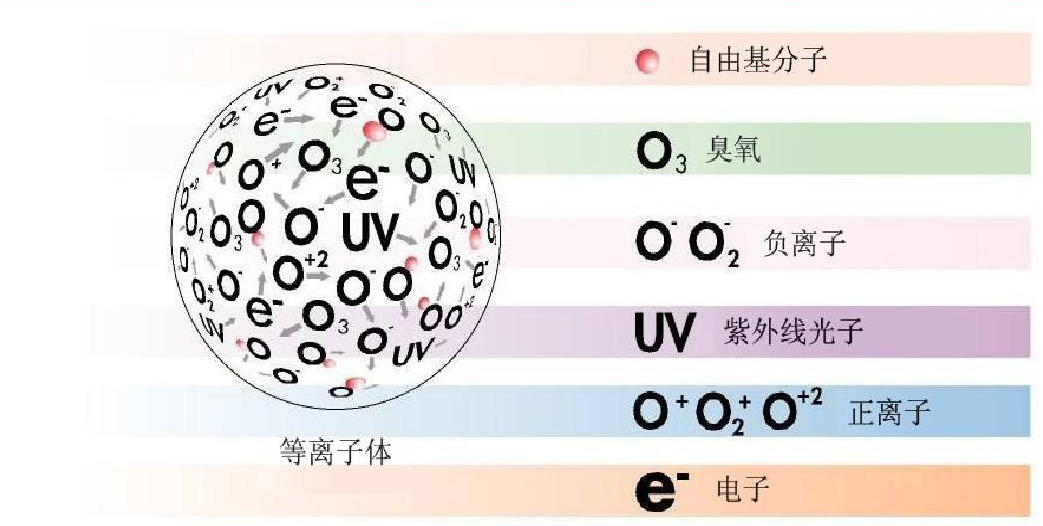

Working principle of plasma cleaning machine

1. Gas ionization: A small amount of gas (such as oxygen, argon) is introduced into the equipment, and plasma (containing ions,

electrons, and free radicals) is formed through high-frequency electric field ionization.

2. Surface bombardment: High-energy particles hit the surface of the material to physically remove pollutants (such as

micron-level cleaning).

3. Chemical activation: The active particles in the plasma react with the surface to introduce polar groups such as hydroxyl

(-OH) and carboxyl (-COOH).

Advantages of plasma treated carbon fiber materials

In order to ensure that the application of carbon fiber materials in automotive components can meet the requirements of high performance and reliability, plasma surface treatment becomes an important pretreatment step, which can effectively optimize the bonding strength and long-term durability of carbon fiber materials.

Through plasma surface treatment, polar functional groups can be introduced on the surface of carbon fiber materials. After treatment, its surface contact angle is reduced from 102.52° to 3.74°, proving that plasma significantly improves the surface wettability, which is beneficial to the full contact between the resin and the carbon fiber, thereby improving the bonding strength and reliability.