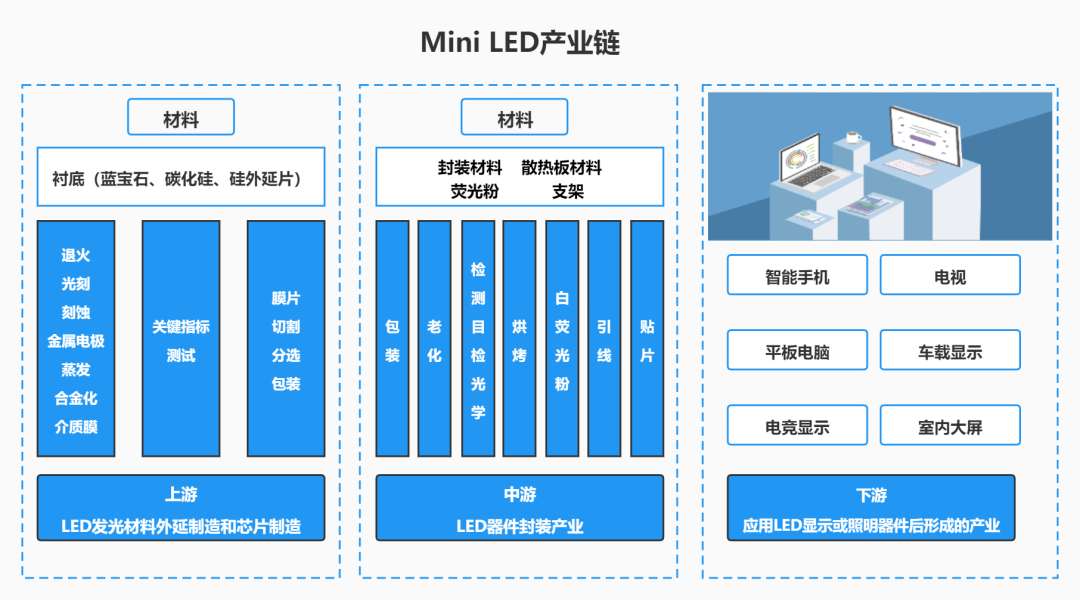

In the LED industry chain, the upstream is the epitaxial manufacturing of LED luminescent materials and chip manufacturing, the midstream is the LED device packaging industry, and the downstream is the industry formed by the application of LED displays or lighting devices. Developing packaging technologies with low thermal resistance, excellent optical properties, and high reliability is a necessary path for new LEDs to become practical and enter the market.

Packaging is the link between industry and market. Only when packaged well can it become a terminal product and be put into practical application.

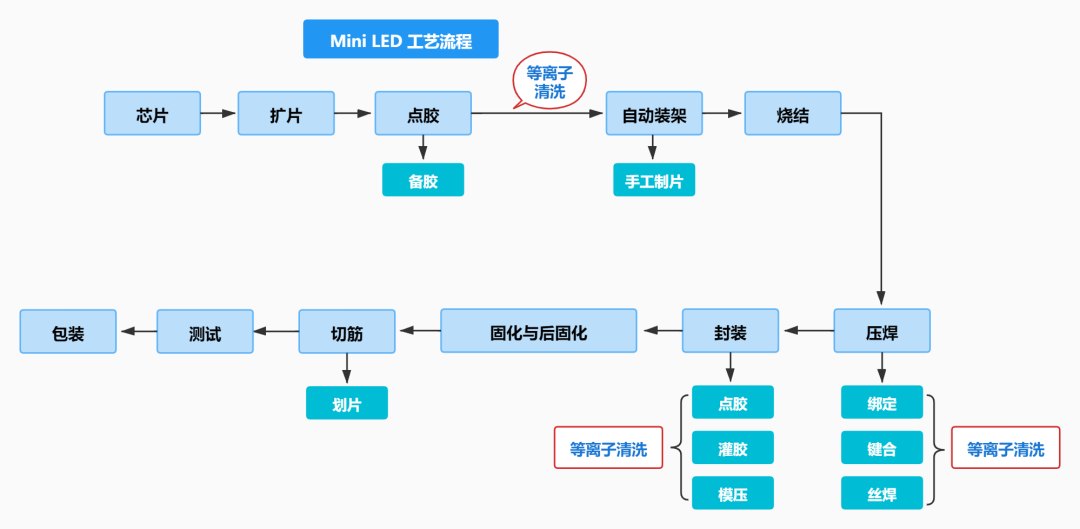

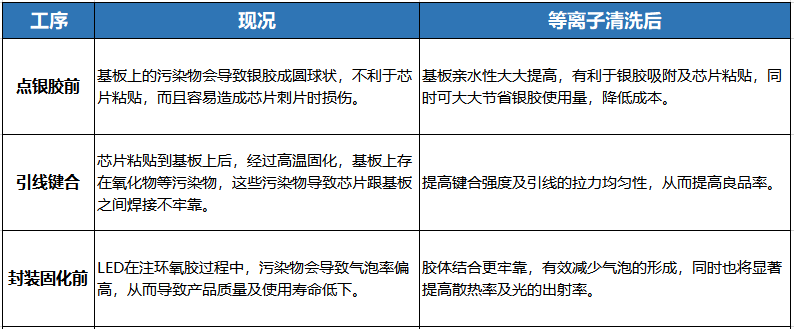

In the packaging process of Mini LED, if there are particle pollutants, oxides, and epoxy resin pollutants on the chip and substrate, it will directly affect the yield of Mini LED products. Plasma cleaning before glue dispensing, lead bonding, and packaging curing during the packaging process can effectively remove these pollutants.

1、 Principles of Plasma Cleaning

Chemical or physical processes are used to treat the surface of an object, achieving molecular level pollutant removal (usually with a thickness of 3-30nm), thereby improving the surface activity of the object. The pollutants to be removed may include organic matter, epoxy resin, photoresist, oxides, microparticle pollutants, etc. Corresponding to different pollutants, different cleaning processes should be adopted. Depending on the selected process gas, plasma cleaning can be divided into:

Chemical cleaning: Plasma cleaning, also known as PE, where surface reactions are mainly chemical reactions.

Physical cleaning: Plasma cleaning, also known as sputtering corrosion (SPE), where surface reactions are mainly physical reactions.

Physical and chemical cleaning: Both physical and chemical reactions play important roles in surface reactions.

2、 Mini LED packaging process flow

3、 Application of Plasma Cleaning in Mini LED Packaging Process

In the Mini LED packaging process, different cleaning processes can achieve ideal results for different pollutants and based on the substrate and chip materials. However, using the wrong process gas scheme can lead to poor cleaning results and even product scrapping. For example, if silver chips are processed using oxygen plasma technology, they may be oxidized, blackened, or even scrapped. In general, particulate pollutants and oxides are cleaned by plasma using a mixture of hydrogen and argon gas. Gold plated material chips can use oxygen plasma to remove organic matter, while silver material chips cannot. Choosing the appropriate plasma cleaning process in Mini LED packaging can be roughly divided into the following three aspects:

By comparing the contact angle data before and after plasma cleaning, it can be seen that the activation of the material surface, removal of oxides and microparticle pollutants, can be directly demonstrated by the tensile strength and wettability of the bonding leads on the material surface.

4、 Shengding Plasma Cleaning Machine

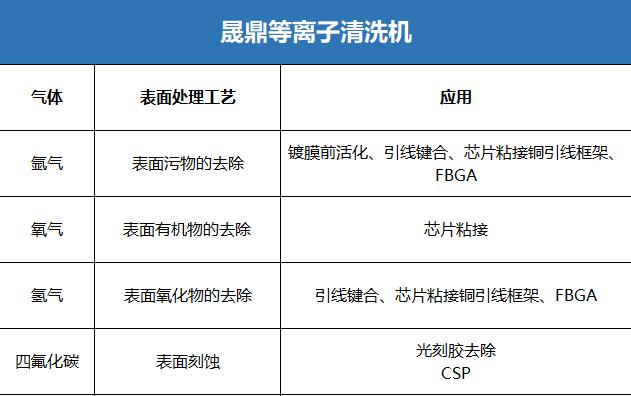

The choice of plasma cleaning in packaging technology depends on the requirements of subsequent processes for the material surface, the characteristics of the material surface, chemical composition, and the properties of pollutants. Plasma cleaning machines can enhance the adhesion, wettability, and reliability of samples, and different processes will use different gases.