Why remove photoresist?

As is well known, photoresist is the core material for semiconductor wafer manufacturing. In the wafer manufacturing process, photolithography accounts for approximately 35% of the total wafer manufacturing cost and 40-50% of the total wafer process time, making it the most critical process in semiconductor manufacturing.

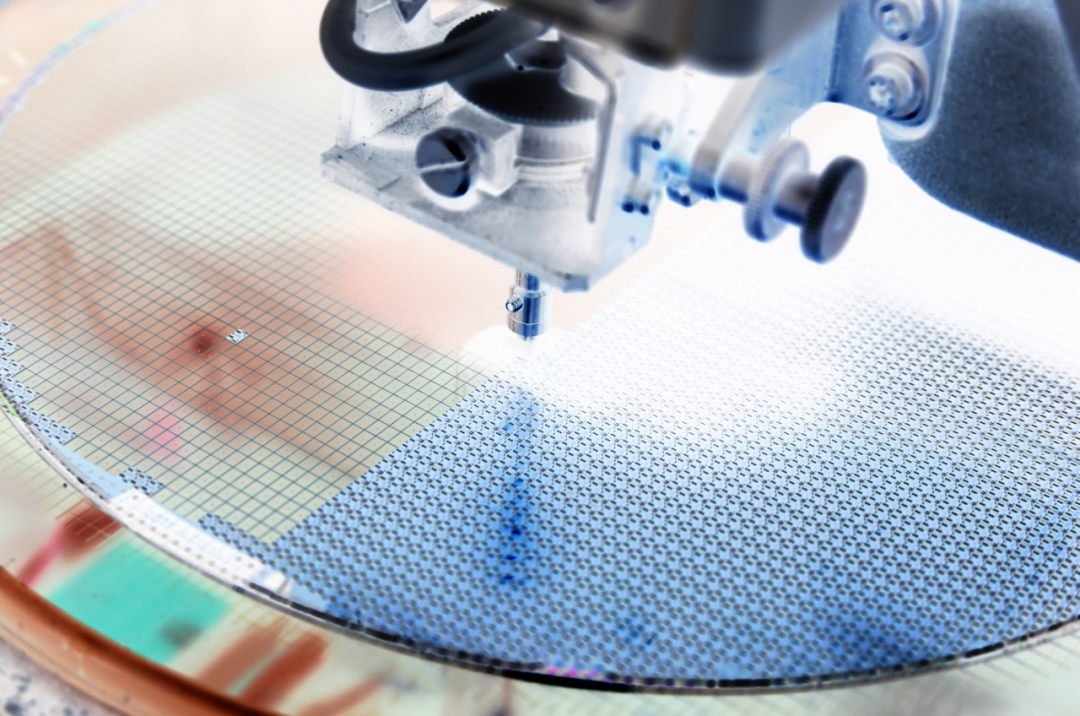

An indispensable step in the lithography process is wafer debonding. After completing the process of pattern copying and transfer, the remaining photoresist on the wafer surface needs to be completely removed through the debonding process.

How to remove photoresist?

The semiconductor photoresist removal process is generally divided into two types: wet photoresist removal and dry photoresist removal. Compared to wet debonding, plasma dry debonding utilizes high-energy plasma to treat the surface of photoresist. The debonding is thorough and fast, without the introduction of chemicals, reducing corrosion and damage to wafer materials. It is the best way in existing debonding processes.

*Image source: Semiconductor Industry Observation

ICP plasma glue remover

The ICP plasma debonding machine relies on Shengding's years of experience in photoresist debonding, adopts a high-density, low-damage plasma source design, and is equipped with Shengding's mature remote ICP technology to achieve a high-level debonding rate and achieve debonding damage suppression; Adopting an independent chamber structure design, achieving uniform flow field distribution and excellent adhesive removal uniformity.

Product advantages:

● Compatible with mainstream 4-8-inch circular wafers

● Can process two wafers at a time, maintaining a lower temperature during the processing

● High degree of automation, achieving fully automatic wafer loading and unloading, cleaning process

● High plasma density and good adhesive removal effect

*Equipment glue removal standard

RIE plasma glue remover

The RIE PLASMA debonding machine is a cleaning equipment suitable for wafer surface debonding of silicon-based materials. It can also be used for photoresist removal, silicon carbide etching, dry removal of hard mask layers, surface cleaning after etching, silicon oxide or silicon nitride etching, DESCUM, medium to medium photoresist removal, and other application fields. The material application range is 4-8 inches. The equipment is stable, reliable, easy to maintain, and has high production capacity.

Product advantages:

● High density plasma, high compatibility with various processes

● High uniformity of cleaning and easy maintenance of equipment

● Compact integrated design with minimal footprint