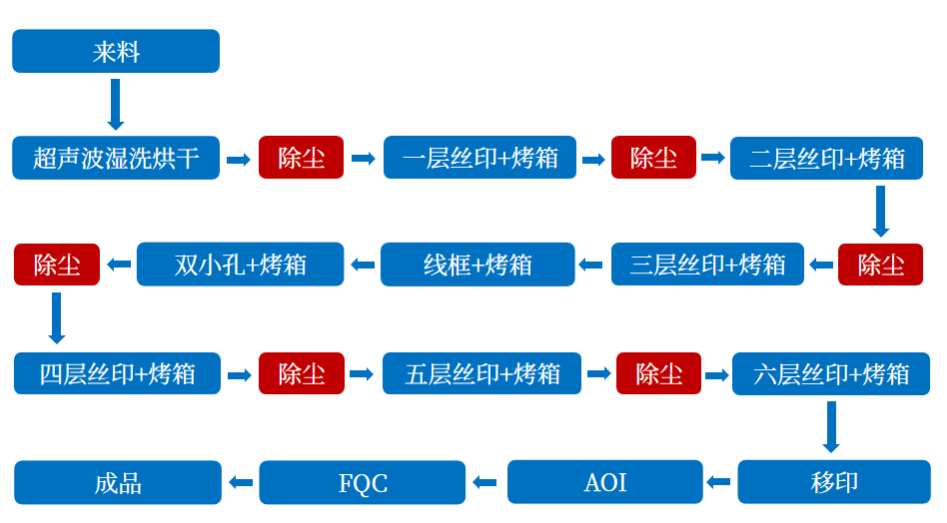

Screen printing process for mobile phone glass cover

In the screen printing process of mobile phone glass cover plates, dust removal work is required before each layer of screen printing, indicating the importance of "dust removal" in the entire screen printing process. Dust removal plays a very important role in improving the efficiency of the entire screen printing process.

The Three Major Factors Influencing Silk Screen Printing Effect

Solutions to dust removal issues

Inadequate handling of dust removal issues can lead to poor ink white spots, discoloration, and other issues. Currently, there are generally two solutions for dust removal:

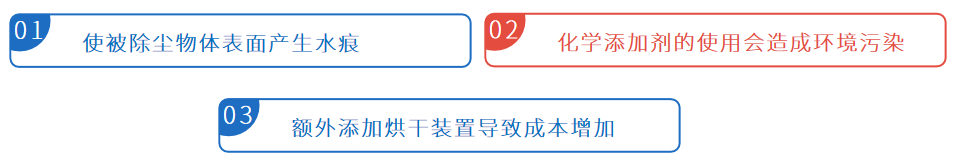

The troubles of wet dust removal

With the emergence of many drawbacks in wet dust removal, advanced dry dust removal technologies have emerged in large numbers. Currently, the methods of dry dust removal include pneumatic sandblasting, particle pneumatic spraying, ultraviolet irradiation, plasma dust removal, laser radiation dust removal, dry ice dust removal, USC dry ultrasonic dust removal, etc.

USC dry ultrasonic dust removal is currently the most advanced dust removal technology!

The application of USC dry ultrasonic dust removal in screen printing process:

The original dust removal method was using a stick dust rod, which generates static electricity during operation, adsorbs dust, and may even scratch the glass panel.

Replace the sticky dust stick with USC ultrasonic dust removal, perform non-contact dust removal on the dust removal head and product surface, and achieve the purpose of dust removal through the energy and vibration transmitted by ultrasonic waves.

During the working process, the blower passes through a high-efficiency filter to produce positive pressure clean gas, which then passes through the ultrasonic pressure chamber of the dust removal head to emit ultrasonic waves for cleaning the glass surface. The negative pressure vacuum chamber instantly sucks away the dust to be cleaned, passes through a medium efficiency filter, and then returns to the blower. The entire cleaning system is a closed-loop system.

PREV:...