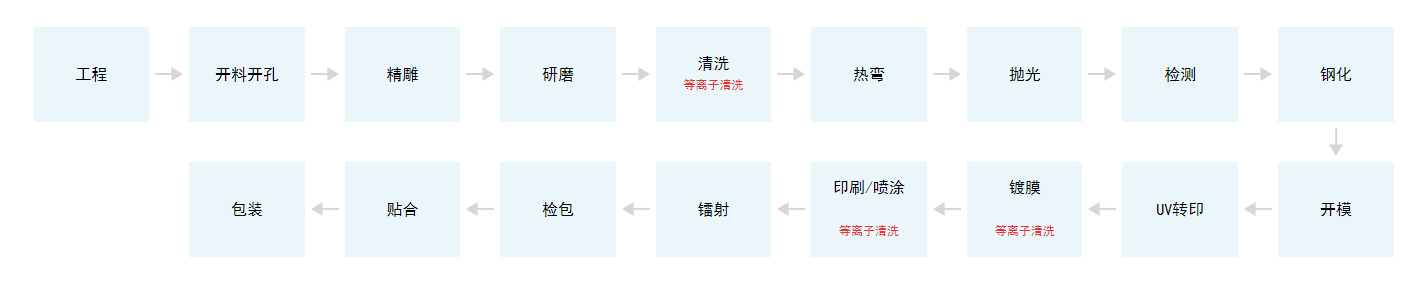

Production and processing process flow of 3D glass cover plates for mobile phones

Plasma cleaning before coating the 3D glass cover of mobile phones

The purpose of coating is to prevent fingerprints and oil stains from sticking and easily erasing. Smooth surface, comfortable touch, and not easy to scratch. Increase the wear resistance of the glass surface.

Pre treatment: Use weak alkaline cleaning agents or solvents to remove oil, moisture and other stains on the surface of the substrate, and achieve better results through plasma cleaning;

Plating AF solution onto the surface of the product to form a film;

Baking: After spraying, take out the glass and place it in an oven (120 ℃, 30 minutes), adjust it to the best according to specific requirements and product conditions;

Before coating, use online atmospheric rotary plasma cleaning. After AF coating, we need a contact angle measuring instrument for contact angle detection to see if it meets factory requirements and improve product yield.

If the coating effect is not good, it needs to be re coated. Before re coating, we need to first remove the coating. The principle of treatment for plating removal is still to turn the hydrophobic surface into a hydrophilic surface, improving the adhesion of the surface, making it easier for AF to plating on the surface of the phone cover.

The 3D glass phone cover is curved, and in the curved part, we need to fit it with the phone frame. Therefore, the curved part still needs to be plasma treated for plating. Due to the small surface area, jet plasma treatment is usually required.