Major mobile phone manufacturers are competing to launch a new generation of foldable phones, including Honor Magic V2 and V Purse, OPPO Find N3 Flip, Huawei Mate X5, Samsung Galaxy Z Fold5 and Galaxy Z Flip5, Xiaomi MIX Fold 3, and more.

Folding screen smartphones have entered the era of popularization!

● Common folding methods in folding mobile phones

At present, the folding methods of foldable phones mainly include: horizontal inward folding, horizontal outward folding, vertical inward folding, and triple folding.

*Common folding phones and folding methods on the market

Folding phones can achieve the functional characteristics of folding and unfolding as desired without easy damage, which cannot be separated from a metal material - stainless steel folding screen for mobile phones.

● What is a stainless steel folding screen for mobile phones?

Due to the flexible nature of the foldable screen, a support plate is required at the bottom of the screen display structure, and stainless steel sheets for mobile phone foldable screens are fully utilized to ensure that the screen can be bent and has sufficient support.

● Solution for Folding Screen Stainless Steel Sheet on Mobile Phone

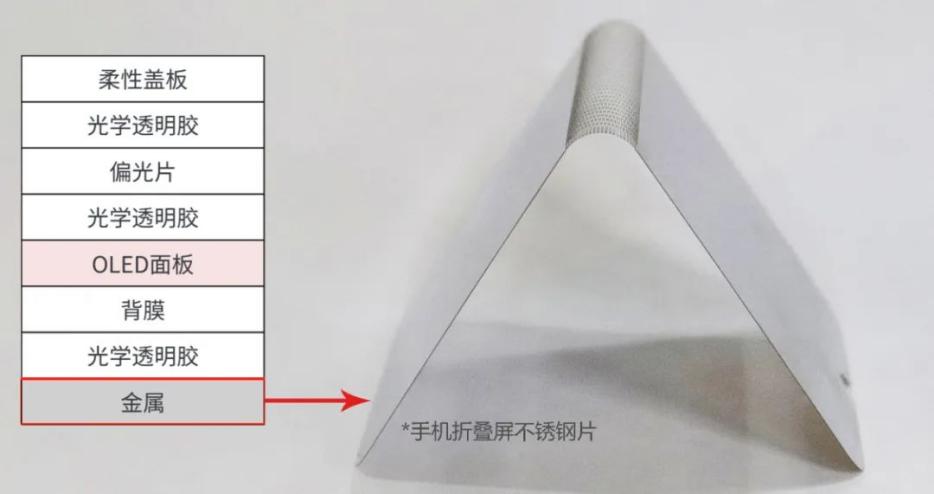

Flexible folding module laminated structure

The laminated structure of a flexible folding module is the core part of a folding phone, usually composed of a flexible cover plate, polarizer, OLED panel, back film, metal, etc. The metal material part is composed of stainless steel sheets for mobile phone foldable screens, which are used to support flexible OLED screens.

In the manufacturing process of foldable mobile phones, it is necessary to tightly bond the flexible OLED screen with the stainless steel sheet of the foldable screen. Before bonding, the surface of the stainless steel sheet needs to be treated with dust removal to remove surface dust and impurities; And through plasma activation treatment, the surface adhesion of stainless steel sheets is improved to ensure the quality and effectiveness of subsequent bonding.

● Dust removal treatment of stainless steel sheets on mobile phone folding screens

The stainless steel sheet for mobile phone folding screen needs to face the problem of surface floating dust treatment in the bonding process. If there are floating dust particles on the surface of the mobile phone folding steel sheet, it may cause the following problems during subsequent bonding:

▶ Surface floating dust particles cause poor adhesion between the folding steel sheet and the screen, resulting in problems such as bubbles and glue overflow

▶ Causing scratches on the flexible OLED screen, resulting in screen damage

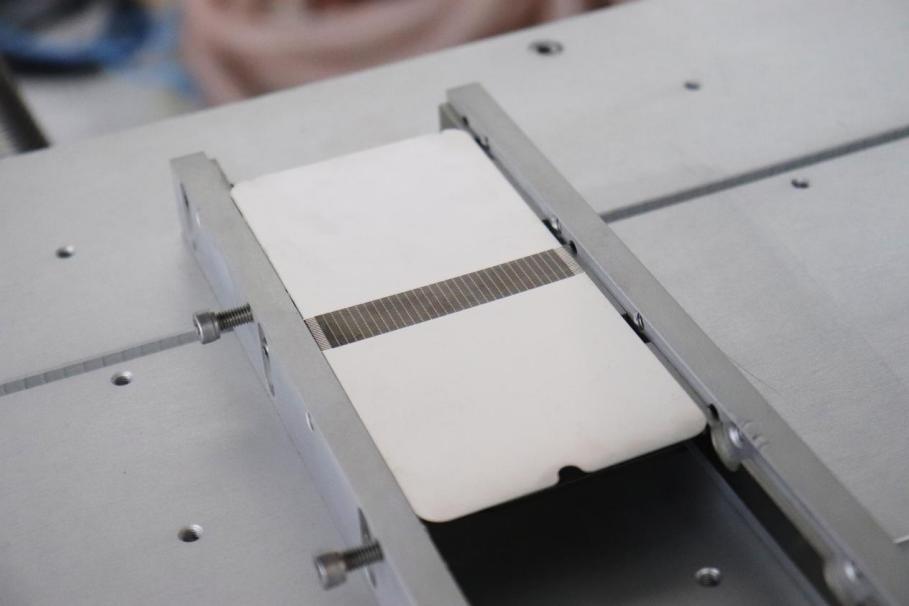

Application case of USC dry ultrasonic dust removal cleaning machine

The Shengding USC dry ultrasonic dust removal cleaning machine can effectively help solve the above problems. Before bonding the stainless steel sheet to the basic display function layer of flexible OLED, USC dry dust removal is used to effectively remove residual floating dust particles on the surface of the steel sheet, avoiding small dust particles from scratching the screen and improving the subsequent bonding quality.

Before Treatment After treatment

*Comparison before and after dust removal (microscope magnified at 40x)

Advantages of USC Dry Ultrasonic Cleaning Machine

✅Non contact dust removal, no damage to the product

✅ Closed loop system, will not cause secondary pollution

✅ Using air as a dust removal medium without the need for water, solvents, drying, and other processes

● Plasma treatment of stainless steel sheets for mobile phone folding screens

Plasma cleaning machines can be used to activate the surface of stainless steel sheets, improve material surface activity, improve wettability and surface adhesion, and solve the problem of poor adhesion.

Application case of wide width plasma cleaning machine

|

|

Contact angle before processing: 16.558° | Contact angle after processing: 108.488° |

The comparison of contact angle data before and after plasma treatment shows that the water droplet angle of the folded stainless steel sheet of the mobile phone is significantly reduced, and its surface wettability is improved, ensuring a good bonding effect in the future.

Wide plasma advantage

● Ultra long processing length;

● Unique patented spray gun that does not cause electrode wear and tear;

● Stable excitation power supply, ensuring plasma uniformity and stable processing;

● Unique patented software, user-friendly operation interface, easy to operate and maintain;

● Three times longer service life and lower failure rate;

● According to actual needs, customize gas formulas and automation methods

PREV:...