With the development of the times, people are no longer satisfied with exploring the real world and have begun to explore the stage of mixed reality (MR), which has made considerable technological progress today in 2022.

1 About VR/AR

Compared to the popularity of mixed reality (MR), we are more familiar with augmented reality (AR) and virtual reality (VR), and they have become an indispensable part of people's lives, widely used in entertainment, education, medical and other fields.

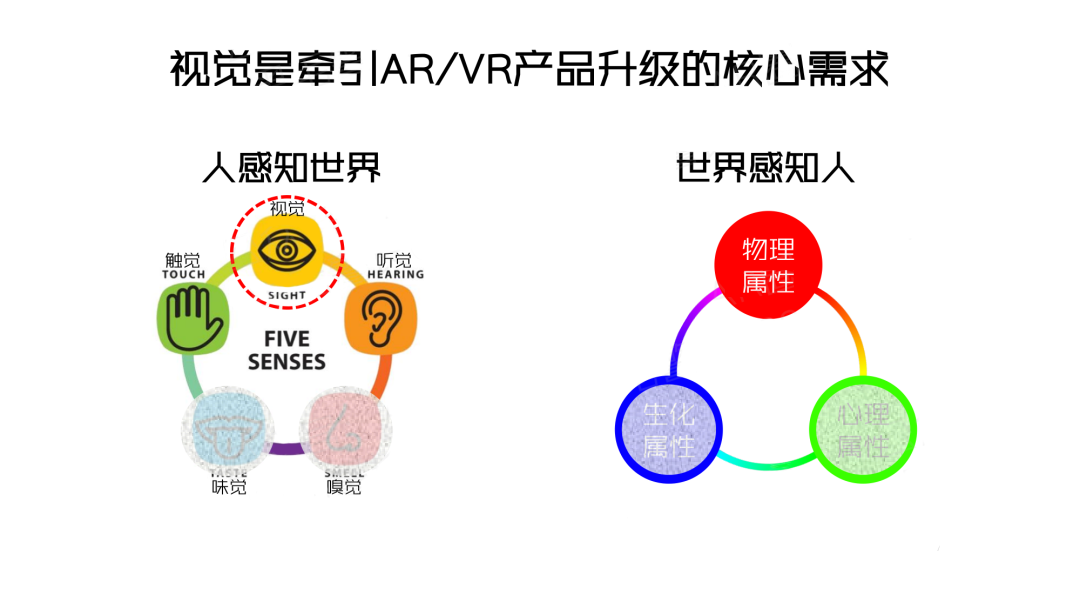

AR/VR, as a currently popular virtual sensory interaction technology, satisfies people's infinite pursuit of visual senses. So vision is also a core requirement for upgrading AR/VR products, and display technology has become one of the core technologies driving the development of the AR/VR industry.

2 Display Technology

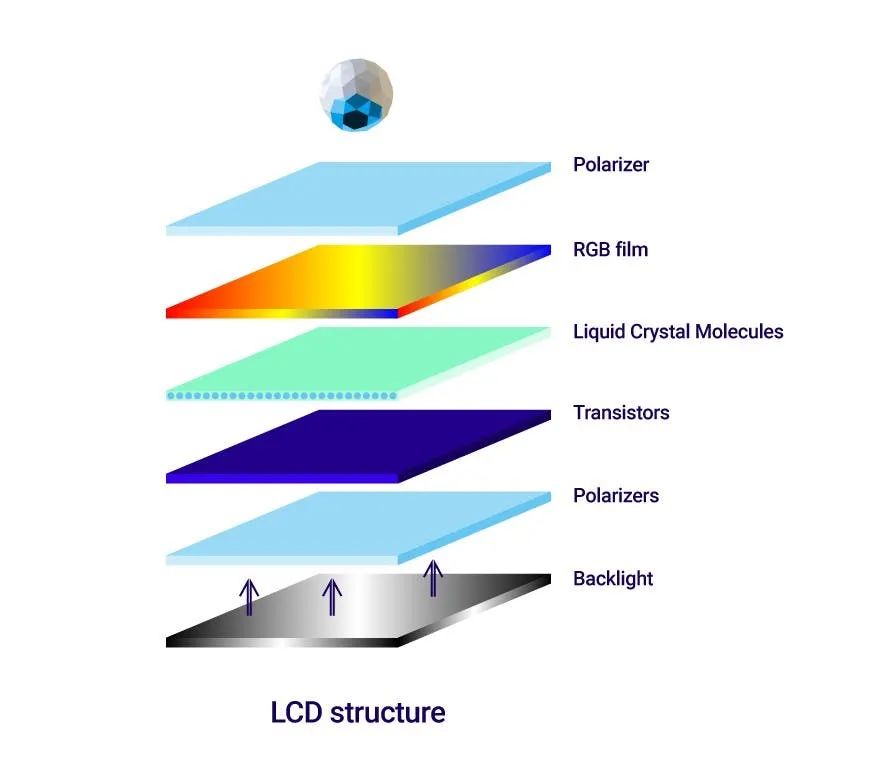

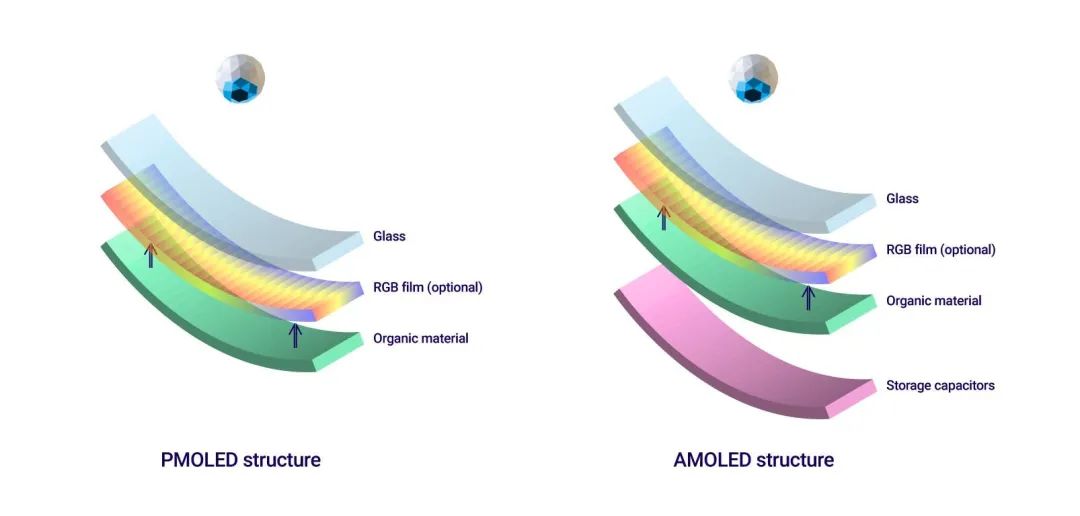

Currently, AR/VR mainly uses display technology systems such as liquid crystal displays (LCDs) and organic light-emitting diode screens (OLEDs).

Image from:Fundamentals of display technologies for Augmented and Virtual Reality,By AkshayKore

In terms of performance, organic light-emitting diode screens (OLEDs) are far superior to liquid crystal displays (LCDs). OLEDs generate visible light through the injection or recombination of charge carriers, and are a type of light-emitting device that does not require external backlighting. Therefore, their structure is relatively simple and can be very thin. In addition, OLED has higher contrast, better color restoration effect, and higher resolution, so most fully immersive headsets use OLED display technology.

Image from:Fundamentals of display technologies for Augmented and Virtual Reality,By AkshayKore

3 USC and plasma technology applied in OLED

Application of POL process

Function:

(1) Remove residual surface dirt particles from upstream processes;

(2) Clean the organic matter on the surface of flexible OLED, improve the water droplet angle, and enhance the reliability of the product;

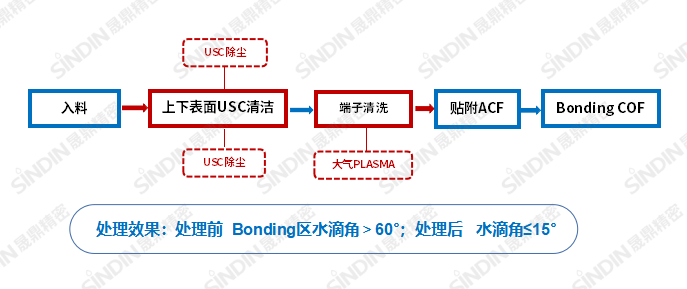

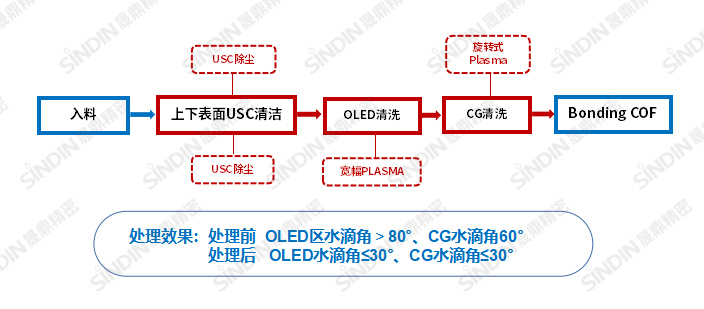

Application of COF process

Function:

(1) Remove residual surface dirt particles from upstream processes;

(2) Clean the organic matter on the surface of flexible bonding, improve the water droplet angle, and enhance the reliability of the product;

Application of D-Lami process

Function:

(1) Remove residual surface dirt particles from upstream processes;

(2) Clean the organic matter on the surface of flexible OLED and CG, improve water droplet angle, reduce GDS occurrence, and reduce foreign objects to enhance the reliability of the product;