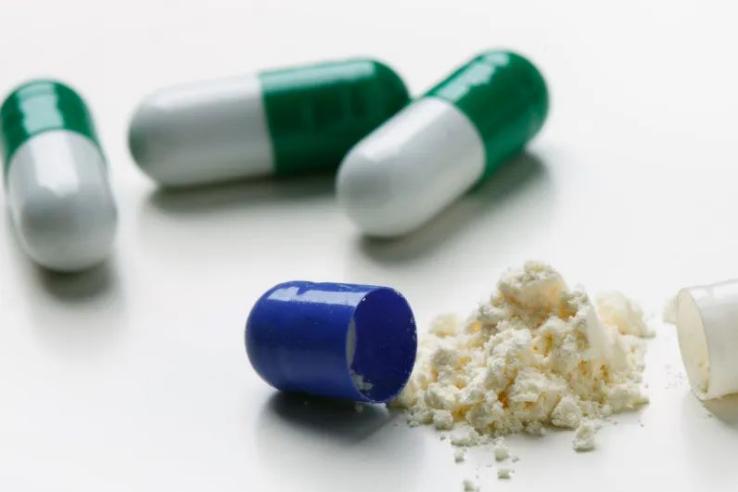

In the fields of coatings, pharmaceuticals, chemical industry, etc., a deep understanding of the wettability of powders plays an important guiding role in the processing, molding, and application of powders.

How does the wettability of powder affect industrial production?

In the preparation process of powder coatings, powder particles need to be evenly dispersed in the liquid. Good powder wettability can help the liquid to better infiltrate, facilitate the penetration and diffusion of the liquid in the powder, and improve the adhesion and stability of the coating.

In the pharmaceutical industry, some drugs exist in powder form, and the wettability of the powder directly affects the solubility of the drug, which is related to the therapeutic effect of the drug.

In the chemical industry, some chemical reactions need to be carried out between powder and liquid. If the wettability of the powder is poor, it can lead to uneven or impossible chemical reactions, affecting the quality and yield of the products.

How to evaluate the wettability of powder?

● Sessile drop

Seat drop method is the most common method in contact angle measurement, used for static contact angle measurement. When measuring the contact angle of powder, it is necessary to press the powder into a tablet for measurement, and then use software to fit the image to obtain its contact angle value.

● Washburn measurement method

The Washburn measurement method is a method that utilizes the capillary siphon effect of liquids in powder materials for measurement.

Hang the sample tube on a mechanical sensor, place the powder sample inside the tube, immerse the lower end of the sample tube in the liquid, and the liquid will rise under the tension of the powder. By recording the weight and corresponding time of the powder sample in real time, and then using the Washburn equation to calculate its contact angle.

Due to the need for liquid to infiltrate the powder and rise into the container, the Washburn measurement method is not suitable for hydrophobic powders. For hydrophobic powders, measuring their contact angle through the seat drop method is a more convenient method. Therefore, in the application of powder contact angle measurement, using the seat drop method is more comprehensive and convenient.

Shengding Precision Powder Industry Application Equipment

In the field of powder, contact angle measuring instruments can be used to measure the surface hydrophilicity and hydrophobicity of powder materials, evaluate the distribution of surface wettability, polarity, and non-polarity.

The SDC-200S scientific research contact angle measuring instrument has complete functions and high expansion performance, with a comprehensive, complete, and accurate fitting measurement method. It can measure the static/dynamic contact angle and interfacial tension of material surfaces, and can be used for measuring the surface properties of powder materials.

Product advantages

✅ Comprehensive, comprehensive, and accurate fitting methods

✅ Zoom zoom lens for clear imaging

✅ More than 20 expansion functions

✅ Automatic liquid injection system