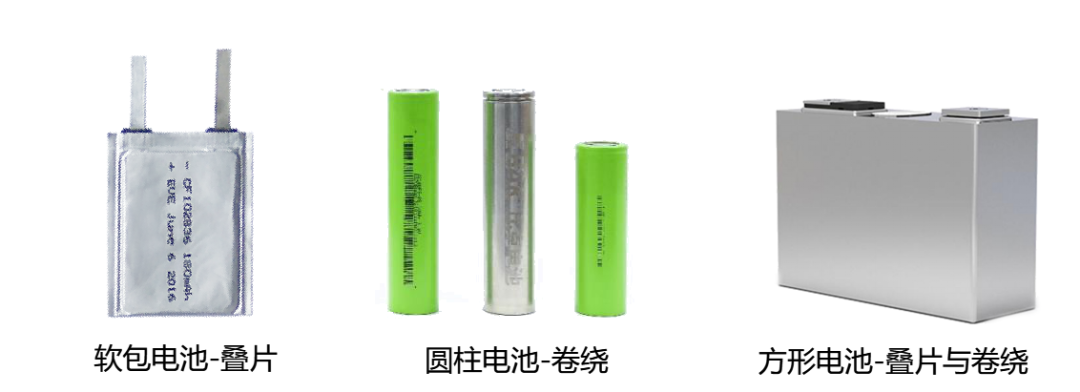

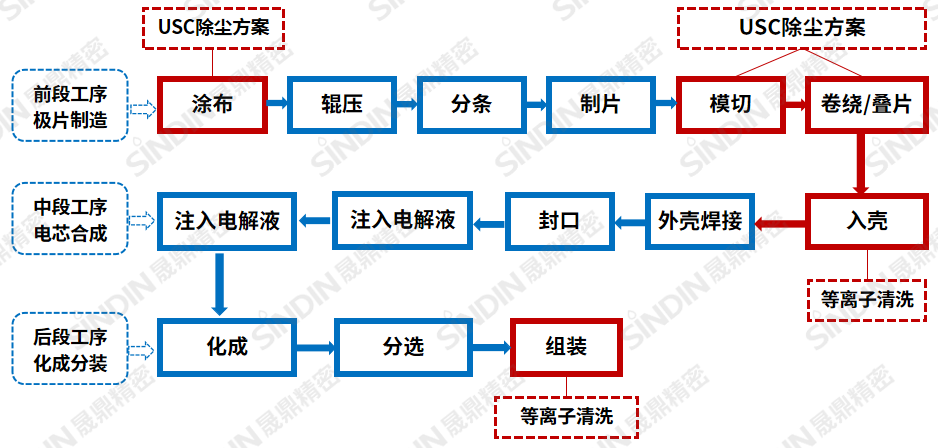

Lithium batteries can be divided into cylindrical batteries, square batteries, and soft pack batteries according to their form, and their production processes have certain differences. However, the overall manufacturing process of lithium batteries can be divided into the front process (electrode manufacturing), the middle process (battery cell synthesis), and the rear process (composition and packaging). The plasma treatment scheme for the cell synthesis process section is as follows:

Plasma treatment of lithium battery aluminum shell in the battery cell synthesis section

Plasma treatment of lithium battery aluminum shell in the battery cell synthesis section

In the battery assembly process, when the battery cells are inserted into the shell, plasma treatment is required to improve the surface energy of the aluminum shell, prepare in advance for aluminum shell welding, and reduce the occurrence of welding defects.

Experiment on Plasma Treatment of Lithium Aluminum Battery Shell

|  |

Experimental Description

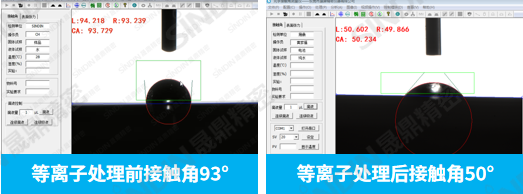

The contact angle of the untreated aluminum shell on the left is 93.729 °. When using a 40 degree dyne pen to stroke the sample, the dyne solution clearly gathers.

After processing, the contact angle of the aluminum shell on the right side is 50.234 °. A 54 dyne pen is used to stroke the sample, and the dyne solution is evenly spread on the surface of the sample.

In the industry standard, the dyne value requirement for plasma treated aluminum shells is 52, indicating that the plasma treatment effect of Shengding is higher than the industry standard.

Shengding Plasma SPA5000 Series

Advantages of SPA5000 series

① Data processing and judgment

Equipped with ARM chips, power accuracy can be maintained at ± 1%

② Increase usage power

Using imported brand PFC chips, the power factor is increased from 0.65 to 0.99 or above, which can reduce useless power by more than 25%

③ Strong anti-interference ability

Adopting imported brand phase-shifting full bridge soft switching circuit, with a response time of less than 0.1s and strong anti-interference ability

④ Digital communication

9 real-time monitoring functions, 18 types of fault alarm functions, supporting both analog and digital communication (also supporting RS232/485 communication interface)