In the battery industry, batteries that have not been assembled for direct use are usually referred to as battery cells, while finished batteries that are connected to a PCM board and have functions such as charge and discharge control and BMS are called batteries. This is what we call a PACK package, which is composed of a certain number of battery cells and can be understood as PACK=m module * n battery cells.

The two most important components of a battery are the battery cell and the protective circuit board (commonly referred to as the PCM board).

The reason why lithium batteries (rechargeable) need to be protected is because the material of the lithium battery itself determines that it cannot be overcharged, discharged, overcurrent, short circuited, or charged or discharged at ultra-high temperatures.

The most commonly used types of cells in PACK are square, cylindrical, and soft pack cells.

As is well known, battery PACK is the core energy source of new energy vehicles, providing driving electricity for the entire vehicle. The main components of a battery pack are the battery cell, electrical system, thermal management system, housing, and BMS.

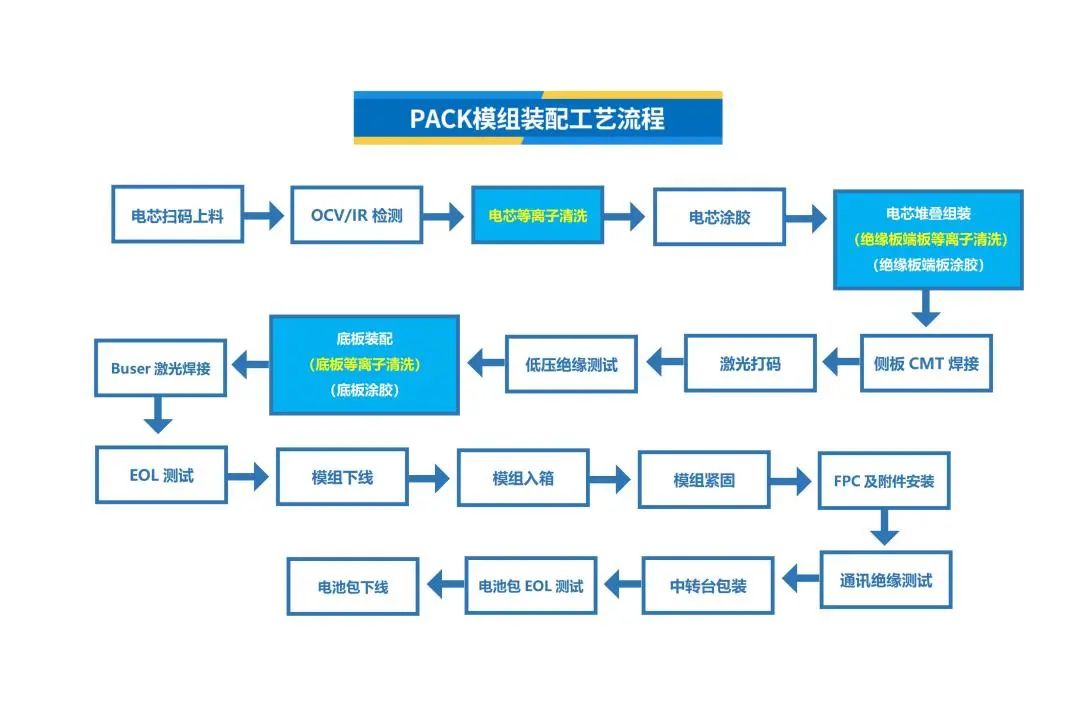

PACK module assembly process flow

Cell sorting

The purpose of battery cell sorting is to select and match battery cells with good electrical performance consistency into a group, to ensure the consistency of the electrical performance of the module or pack, and to extend the service life of the pack.

A module is generally composed of multiple battery cells combined in series and parallel. If the consistency of individual cells is poor, the lifespan of the module will be shortened, and the performance of the module will ultimately be determined by the worst individual cell.

Plasma cleaning of battery cells

Before assembling the battery module, plasma cleaning is required to remove surface pollutants, improve surface energy, and prepare for the next coating process.

Insulation board end plate plasma cleaning machine

According to the process documents, the battery cells are first connected in parallel to form a battery cell group, which is then stacked. A piece of foam is placed between each battery cell group. Before stacking, perform plasma cleaning on the end plates of the insulation board to increase the adhesion between the foam and the surface of the battery cells.

Bottom plate plasma cleaning

Before assembling the bottom plate, use a plasma cleaning machine to prevent gaps or misalignment between the end plate components and the aluminum cover after bonding.

Industry standard (plasma cleaning)

The reliability and quality of products can be improved through plasma surface treatment. At present, it has been widely used in the production process of new energy power vehicles. In the industry, in the process of PACK module assembly, there are requirements for PET tray, PP film, top cover, guard board, aerogel and other projects to meet the requirements of factor standards.

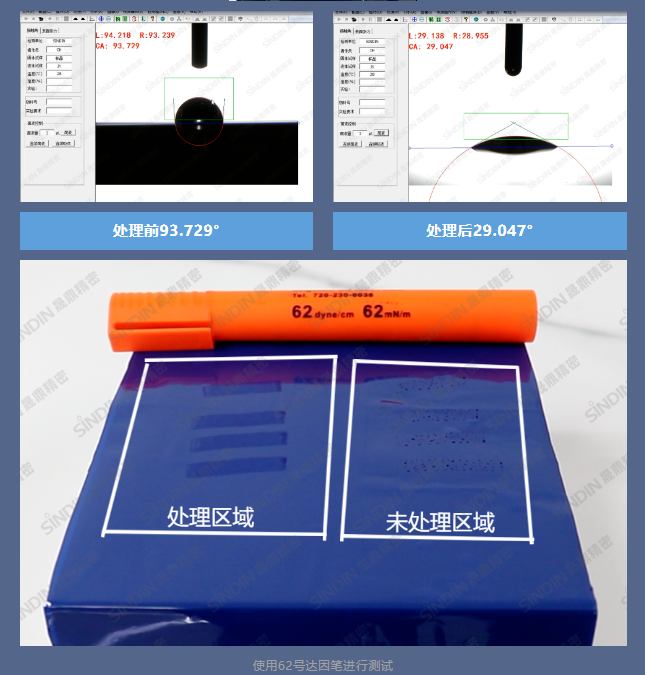

In order to provide you with a more intuitive understanding of the cleaning effect of Shengding Precision's plasma cleaning machine, the following is a comparison of the contact angle test and Dyn pen test data of the power battery blue film before and after plasma treatment.

Experimental operation: Divide the surface of the blue film of the battery cell into two areas, with plasma surface treatment on the left and no surface treatment on the right. After plasma cleaning, the contact angle on the right side that has not been cleaned is 93.729 °, and the contact angle on the left side that has been cleaned is 29.047 °. Testing was conducted using a 62 dyne pen, which visually shows that after plasma surface treatment, the surface energy of the blue film of the battery cell can be improved and the dyne value can be increased.

Prove that plasma cleaning technology can clean the surface of the blue film of the battery cell, roughen the surface, and improve the adhesion of subsequent coating.

PREV:The application of plasma technology in the lithium battery industry

NEXT:Plasma treatment technology improves the wettability of battery separator surface