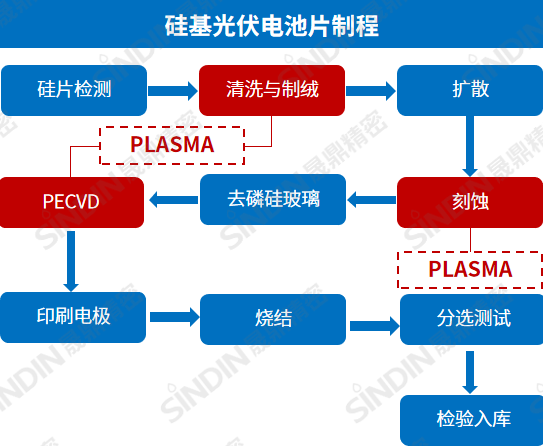

Silicon based photovoltaic cell manufacturing process

From silicon wafers to battery cells:

Taking the current mainstream production process of monocrystalline silicon PERC batteries as an example, the process from silicon wafers to battery cells generally involves:

→ Cleaning and velvet making

→ Diffusion bonding

→ Etching&Dephosphorization Silicon Glass

→ PECVD

→ Printed electrodes&sintering

→ Sorting testing/inspection and warehousing

Plasma cleaning machines can be used in cleaning, velvet making, etching, PECVD and other processes. Let's take a look at the specific applications below.

The application of plasma in battery cell technology

1. Cleaning and Velvet Making

In the cleaning and velvet making process, wet chemical cleaning is generally carried out using alkaline or acidic corrosive liquids. The velvet making effect is not only affected by multiple factors, but also the porous silicon structure is loose and unstable, with a high surface recombination rate.

Plasma cleaning machine treatment plan:

By bombarding the surface of battery cells with high-speed particles from ionized materials, the textured surface can be treated more finely and orderly, and the surface structure can be more stable, reducing the generation of composite centers; It can also simultaneously remove fingerprints and oil stains on the surface of the material, reducing the drying process of wet treatment.

2 Etching&Dephosphorization Silicon Glass

In the previous diffusion process, the photogenerated electrons collected from the front of the PN junction will flow along the phosphorus diffusion area at the edge to the back of the PN junction, causing a short circuit. Therefore, it is necessary to etch the doped silicon around the solar cell to remove the PN junction at the edge of the cell.

Plasma etching technology is usually used to complete this process. Plasma can decompose excess diffused phosphorus through particle blowing, thereby achieving the goal of removing PSG.

3 PECVD

In order to reduce surface reflection and improve the conversion efficiency of the battery, it is necessary to deposit a layer of silicon nitride anti reflection film.

In industrial production, PECVD equipment is often used to prepare anti reflective films. PECVD, also known as plasma enhanced chemical vapor deposition, uses low-temperature plasma as an energy source. The product is placed on the cathode of a glow discharge at low pressure, and the glow discharge is used to heat the product to a predetermined temperature. Then, an appropriate amount of reaction gases SiH4 and NH3 are introduced, and the gas undergoes a series of chemical and plasma reactions, Form a solid thin film on the surface of the product, namely silicon nitride thin film.

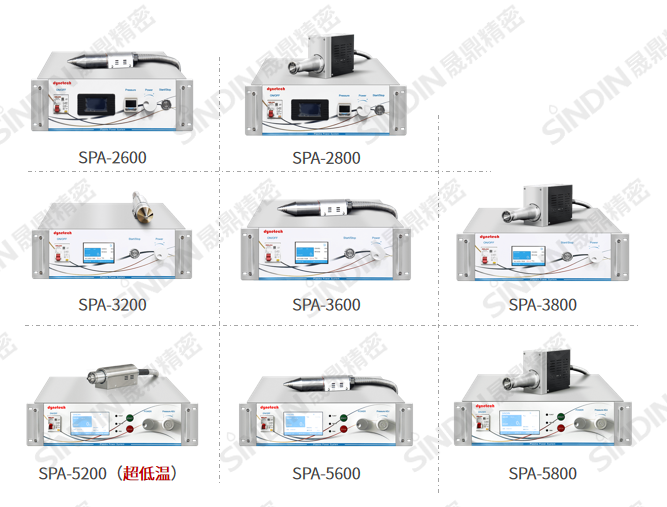

Shengding Plasma Cleaning Machine

1 Atmospheric plasma cleaning machine

Suitable for cleaning and activating photovoltaic glass, battery cells, backplates, frames and other components, it can be paired with direct injection or rotating gun heads, and can be customized for atmospheric plasma assembly line equipment.

2 Wide width plasma cleaning machine

Suitable for cleaning and activating photovoltaic glass, battery cells, backplates and other components, and can customize wide linear plasma assembly line equipment.

3 Vacuum plasma cleaning machine

Suitable for cleaning materials with large areas and complex shapes, can be paired with multiple process gases, and can customize vacuum plasma assembly line equipment.

PREV:The Importance of Plasma Cleaning Machine for PACK Module Assembly

NEXT:Plasma treatment technology improves the wettability of battery separator surface