Lithium battery production and manufacturing process

Case study of plasma cleaning for lithium battery packaging

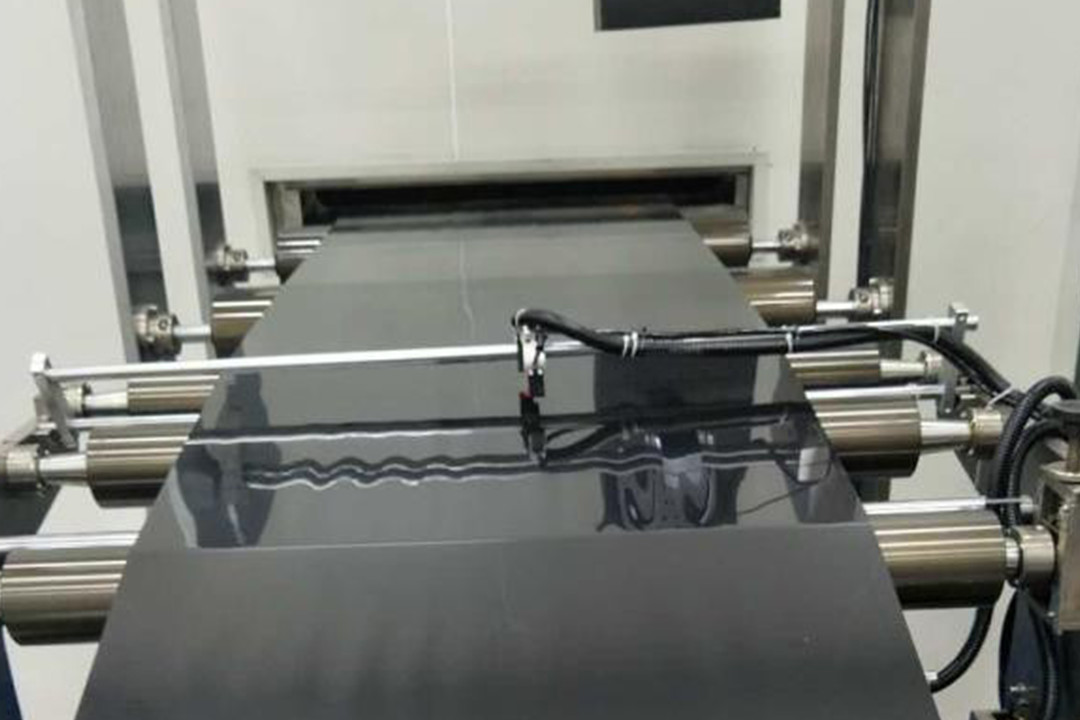

Plasma cleaning before coating the 1-pole plate

The positive and negative electrode plates of lithium batteries are made by coating positive and negative electrode materials on a metal thin film, and plasma cleaning work is required for the positive and negative electrode plates before coating. The single-sided density of the positive electrode coating is ≈ 20-40 mg/cm2 (NCM power type), and the single-sided density of the negative electrode coating is ≈ 10-15 mg/cm2. The material of metal film is generally aluminum foil or copper foil, and the previous cleaning method was wet ethanol solution cleaning, which can easily cause damage to lithium batteries and other components. The use of a plasma cleaning machine not only does not cause damage to the material and produces no residue, but also can remove organic matter on the surface of the material, increase the surface wettability of the film, and improve the uniformity, thermal stability, and safety of the coating.

2. Plasma cleaning before battery welding

If the electrode ears of lithium battery cells are uneven, it can lead to false soldering during welding, which greatly affects the reliability and durability of lithium battery connections. So it is necessary to ensure that the surface of the pole ear is free of invisible dirt and dust to the naked eye. Plasma cleaning before welding lithium batteries can remove impurities such as organic matter or small particles on the surface, preparing for battery welding in advance and reducing welding defects.

3 Plasma cleaning during battery assembly process

In order to prevent battery short circuits and provide insulation during the battery assembly process, it is necessary to apply external adhesive treatment to the battery cells to improve the safety of use. Before applying adhesive, using a plasma cleaning machine to plasma treat the insulation board, end plate, PET film, and other parts can thoroughly clean the surface dirt of the battery cell, roughen the surface of the battery cell, and improve the adhesion of subsequent adhesive or coating.

Summary

Plasma cleaning technology can achieve thorough cleaning effects, stable surface treatment, and effective cleaning of difficult parts in production and manufacturing. So increasing the plasma cleaning process can effectively improve the level of battery manufacturing technology.

PREV:How can plasma improve the reliability of solar photovoltaic panel packaging?

NEXT:Plasma treatment technology improves the wettability of battery separator surface